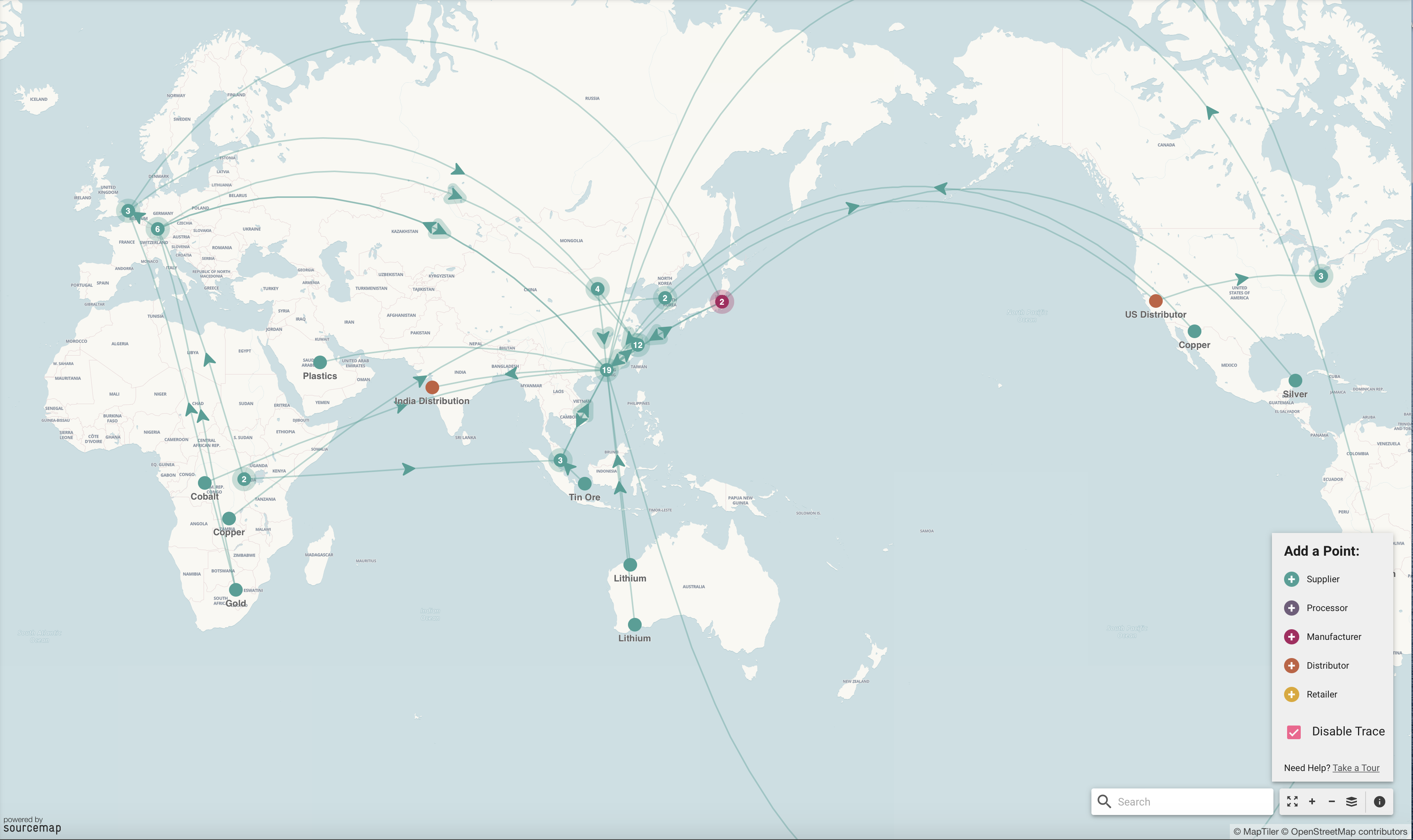

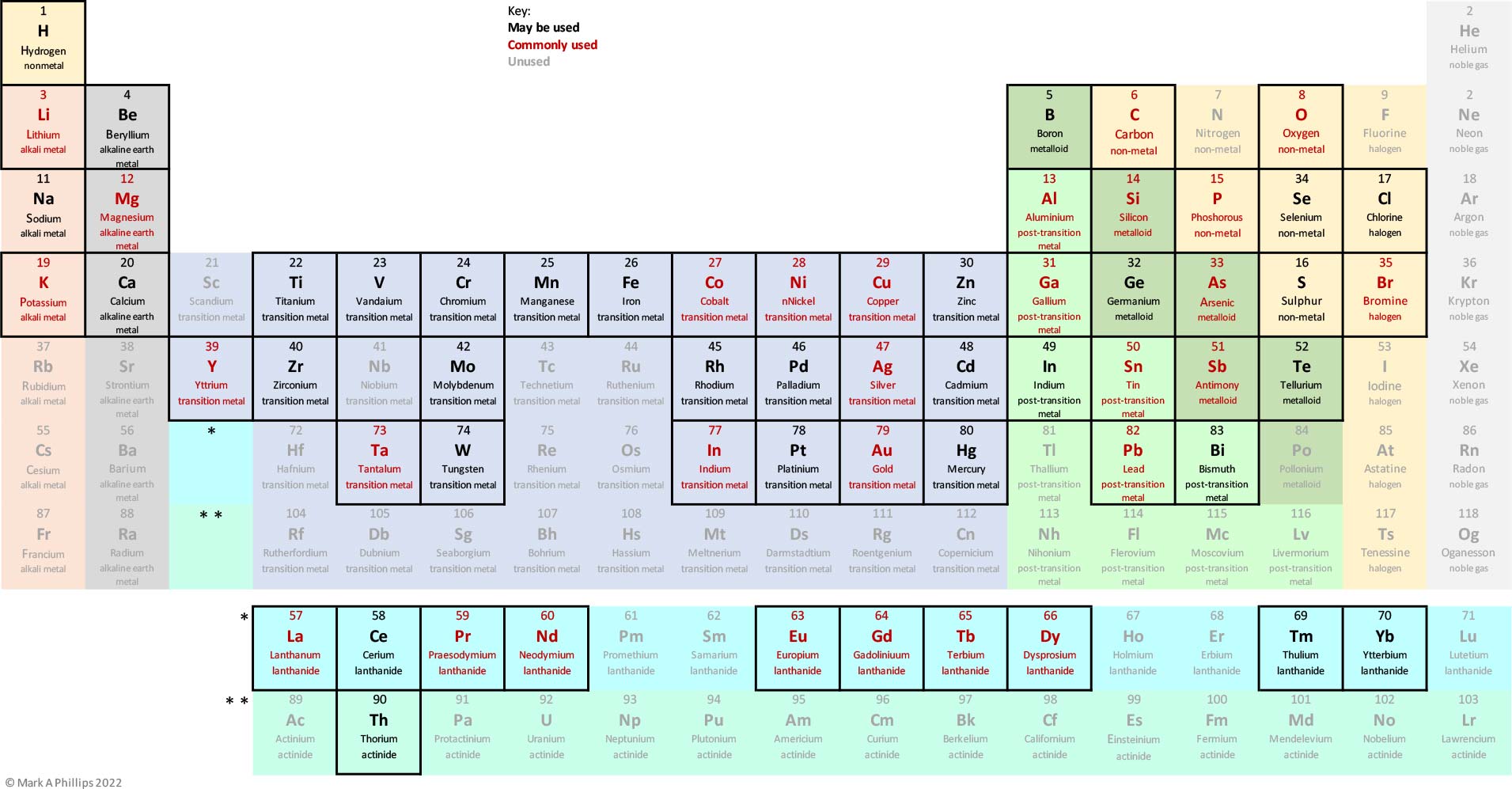

Around 50 of the world’s 90 naturally occurring elements are used in over 25 billion electronic ‘connected things’. That includes 6.4 billion smart phones and over 2 billion PCs. All those device components require different materials to provide the required functionality. A typical smart phone or tablet uses over 30 different elements. A computer may use slightly less, but also has much more plastic and metallic materials incorporated into it.

![[impact2_4]](https://unbroken.solutions/wp-content/uploads/2022/03/impact2_4.jpg)

![[impact2_3]](https://unbroken.solutions/wp-content/uploads/2022/03/impact2_3.jpg)

![[impact2_2]](https://unbroken.solutions/wp-content/uploads/2022/03/impact2_2.jpg)

![[impact2_5]](https://unbroken.solutions/wp-content/uploads/2022/03/impact2_5.jpg)